Performance

5.0/5

- ≤14haverage response time

- 50.0%on-time delivery rate

- US $730,000+{0} orders

Profile

Download report by TüVRheinland

by TüVRheinland

by TüVRheinland

by TüVRheinland- Overview

- Company registration date1996-12-05Floor space(㎡)21055Annual export revenue (USD)6536000Accepted languagesEnglishYears exporting27Years in industry27

- Certifications

- Production capabilities

- Production machines56

- Quality control

- Product Support traceability of raw materialsYesProduct inspection methodInspection of all products, According to client's requirementQuality control conducted on all production linesYesQA/QC inspectors3

- Trade background

- Main marketsDomestic Market(35%), Western Europe(12%), South America(8%)Main client typesRetailer, Wholesaler, Brand business, For private use, Manufacturer

- R&D capabilities

- Customization optionssample processing, graphic processing, customized on demandR&D engineers5R&D engineer education levels3 graduate, 2 technicalSchool

Video tips

02:40

02:40 00:20

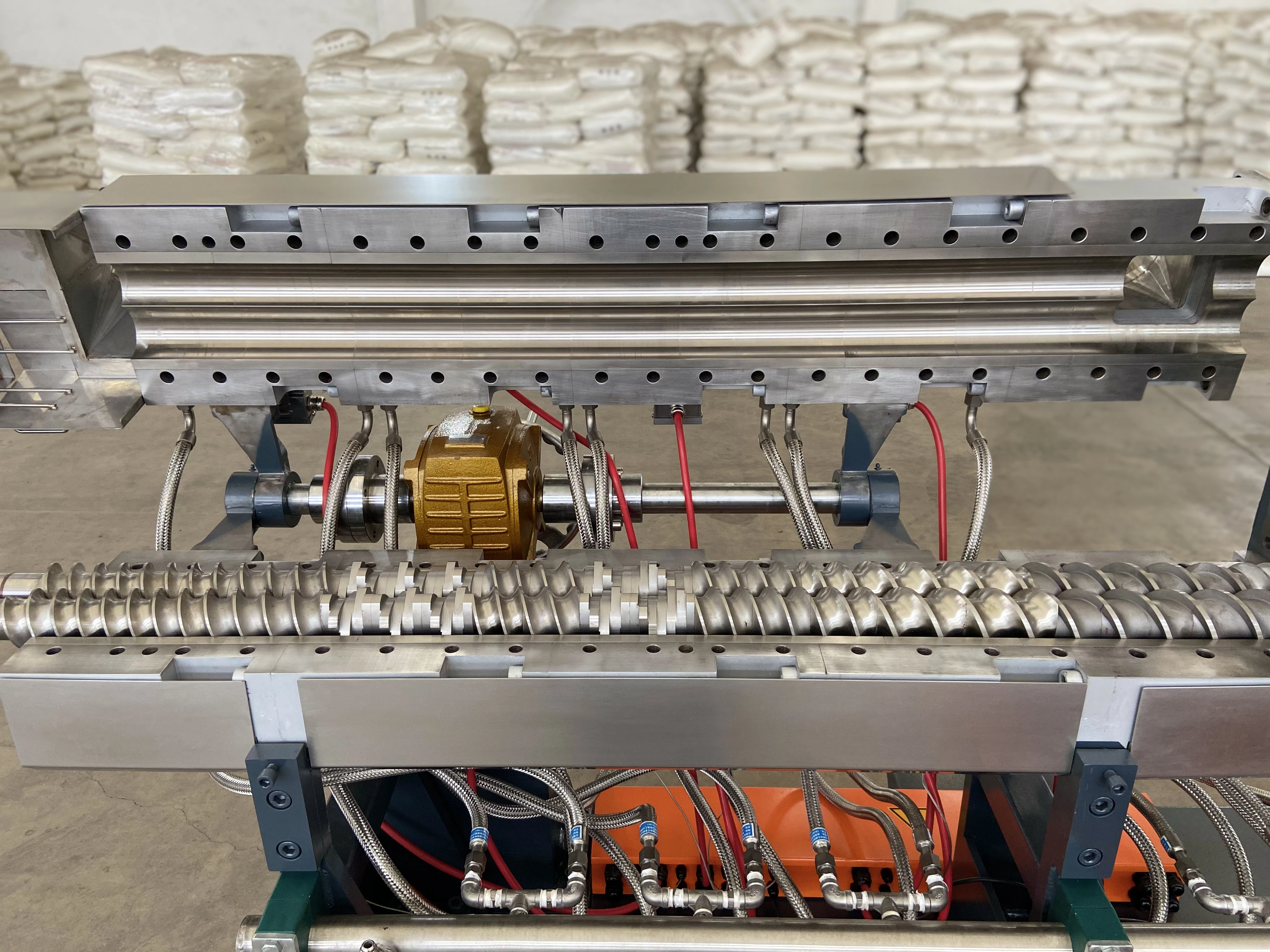

00:20Xinda SJW-100 Co-kneader Pre-Delivery Inspection for PVC Insulation Compounds 300-600kg/h

00:25

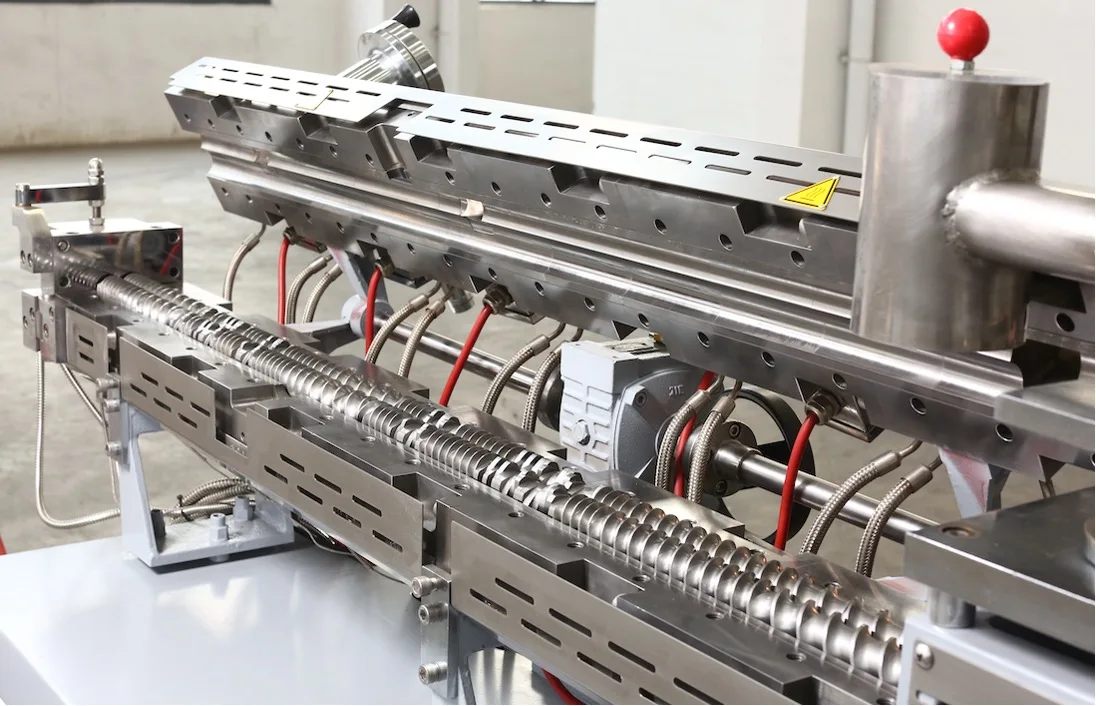

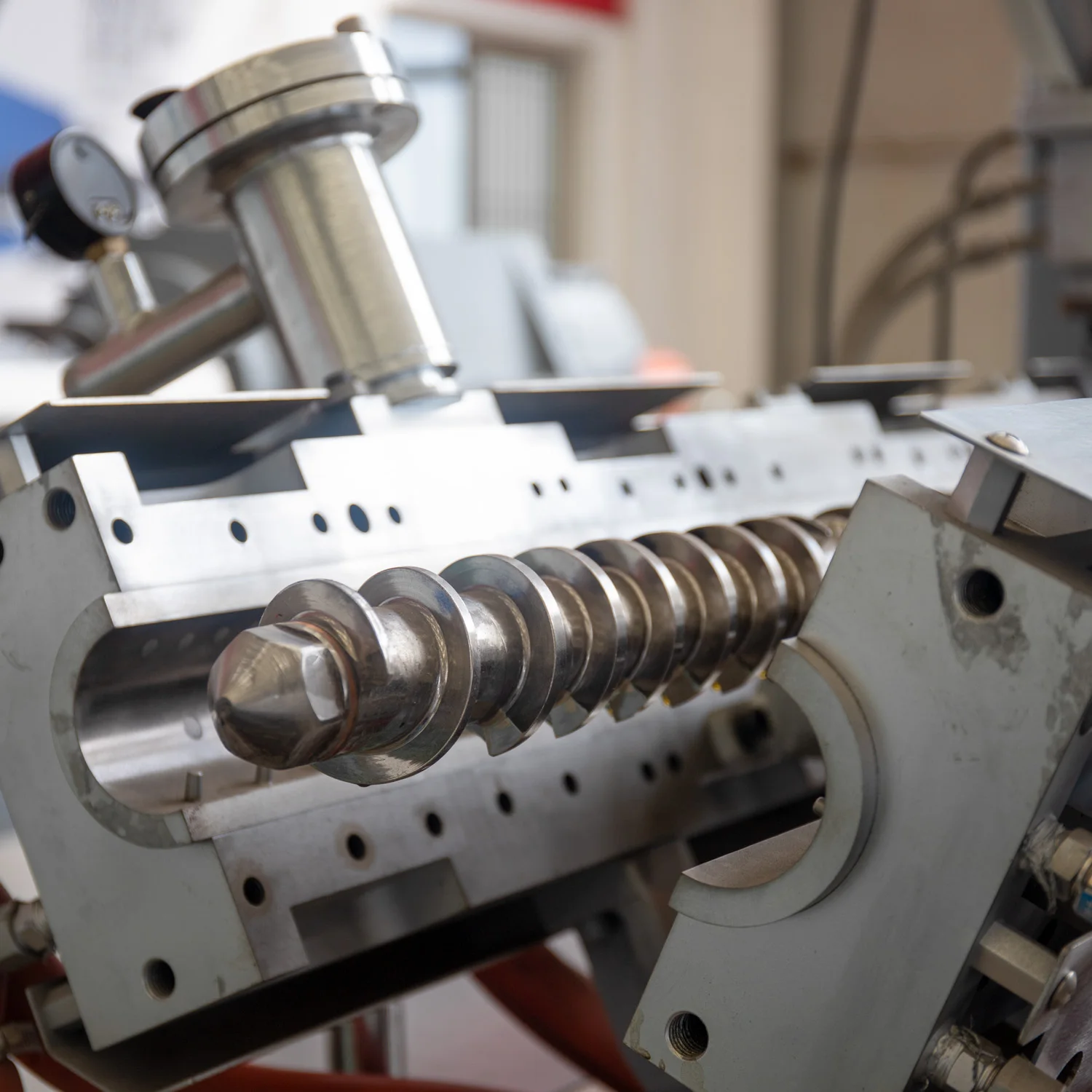

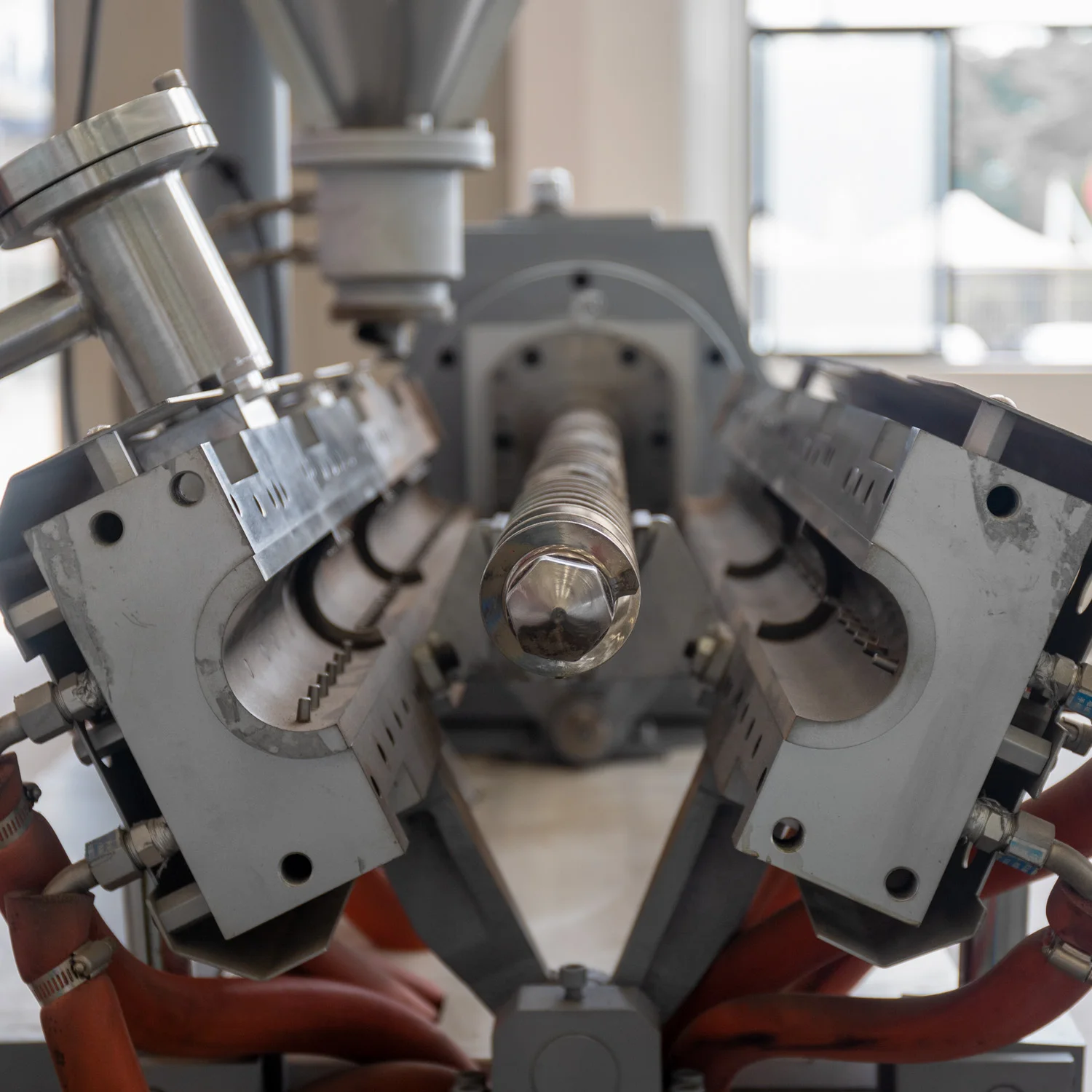

00:25Xinda PSHJ-35 Clamshell Barrel Twin Screw Extruder

00:45

00:45PVC Compounds Single Screw Extruder

Efficient Blending of Liquid Components

Barrel can be opend

00:21

00:21Plastic Compound Lab Twin Screw Extruder For Master batches

01:03

01:03Various Application Plastic Modification Twin Screw Extruder Pelletizing Machine Masterbatch Production Line

00:22

00:22Cable Granule Granulator Single Screw Extruder Eco Friendly Biodegradable PVC Plastic Granule Raw Material Making 15-25,15-25

00:22

00:22Competitive price with good quality pvc cable compounding extruder